What is an Induction Motor :All You Need to Know

We understand that the primary role of a motor is to convert energy from one form to another, such as electrical to mechanical. Motors can be classified based on the type of power supply they use, including AC motors and DC motors. Within these categories, various types of motors exist, such as induction motors, reluctance motors, DC shunt motors, PMDC motors, stepper motors, synchronous motors, and more.

This article provides an overview of different types of induction motors and their operation. Induction motors, also known as asynchronous motors, are the most commonly used AC motors. They operate at speeds lower than synchronous speed, which refers to the rotational speed of the magnetic field in the stator.

What is an Induction Motor?

An induction motor, equipped solely with amortisseur windings, stands as the simplest electrical machine from a construction perspective in most cases. Operating on the principle of induction, an induction motor induces an electromagnetic field into the rotor as the rotating magnetic field of the stator intersects with the stationary rotor. Widely deployed in industrial, commercial, and residential settings, induction machines represent the predominant type of motor. They operate as three-phase AC motors and boast the following characteristic features:

- Simple and robust construction

- Cost-effective with minimal maintenance requirements

- High reliability and reasonably high efficiency

- No need for an additional starting motor and no requirement for synchronization

- What are the Basic Components of an Induction Motor?

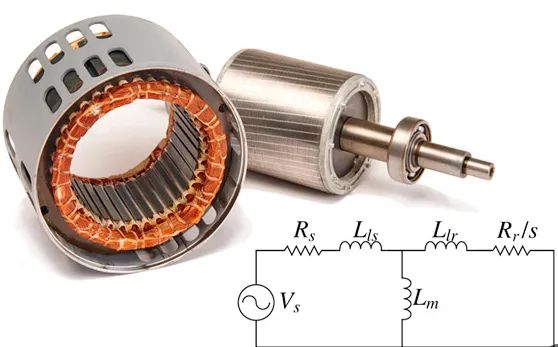

- An induction motor comprises primarily two components: the Stator and the Rotor.

Stator:

The stator consists of multiple stampings with slots to accommodate three-phase windings, wound for a specific number of poles. These windings are geometrically spaced 120 degrees apart. Induction motors utilize two types of rotors: Squirrel cage rotor and Wound rotor. Operating without the need for DC field current, induction motors induce rotor voltage in the rotor windings rather than establishing a physical connection via wires.

Rotor:

The rotor serves as the moving component within the electromagnetic circuit. The most prevalent type of rotor is the squirrel cage rotor, consisting of a cylindrical laminated core featuring axially arranged parallel slots to accommodate the conductors. Each slot contains a copper, aluminum, or alloy bar. Often referred to as an anchor, the rotor of three-phase induction motors derives its name from the anchor-like shape utilized in early electrical devices. While in electrical equipment, the winding of the anchor would be induced by the magnetic field, in three-phase induction motors, the rotor assumes this function.

An induction motor shares the same physical stator as a synchronous machine but features an alternative rotor construction. While induction motors can function as either motors or generators, they are primarily utilized as induction motors.

Operating Principle:

The working principle of an induction motor revolves around the AC in the motor's rotor, which is essential for generating torque through electromagnetic induction resulting from the rotary magnetic field of the stator winding.

Types of Induction Motor:

Induction motors are divided into two main types: single-phase induction motors and three-phase induction motors. As their names imply, a single-phase induction motor is connected to a single-phase AC power supply, while a three-phase induction motor can be linked to a three-phase AC power source. Furthermore, these types of induction motors are further categorized into several subtypes, with single-phase motors classified into four types and three-phase motors into two types.

Single-phase Induction Motor:

The single-phase induction motor exhibits a non-self-starting behavior. Upon connection to a single-phase power supply, the main winding carries an alternating current. It's rational to opt for the most economical and low-maintenance type of motor for frequent use. These motors come in various types based on their starting methods since they are not self-starting. These include split-phase, shaded pole, and capacitor motors. Additionally, capacitor motors are further categorized as capacitor start, capacitor run, and permanent capacitor motors. The permanent capacitor motor is depicted below.

In these motor types, the start winding may feature a series capacitor and/or a centrifugal switch. Upon application of the supply voltage, the current in the main winding lags behind the supply voltage due to the main winding impedance. The current in the start winding leads or lags the supply voltage depending on the starting mechanism's impedance.

The angle between the two windings provides a sufficient phase difference to generate a rotating magnetic field, thereby producing a starting torque. When the motor reaches 70% to 80% of synchronous speed, a centrifugal switch on the motor shaft opens, disconnecting the starting winding.

Types of Single-Phase Induction Motor:

Single-phase induction motors are classified into four types: Split Phase, Capacitor Start, Capacitor Start & Capacitor Run, and Shaded Pole Induction Motor.

Split Phase Induction Motor:

Also known as a Resistance Start Motor, the split-phase induction motor comprises a stator and a single cage rotor, with the stator featuring two windings known as the starting winding and the main winding. These windings are positioned 90 degrees apart in space. The starting winding has lower inductive reactance and higher resistance, while the main winding has extremely low resistance and high inductive reactance.

This motor type is cost-effective and suitable for loads that start easily, where the starting torque can be limited. However, it is not suitable for drives requiring above 1 KW due to the low starting torque. Applications of the split-phase induction motor mainly include washing machines, floor polishers, AC fans, mixer grinders, blowers, centrifugal pumps, drilling machines, and lathe machines.

Capacitor start induction motors are utilized in applications where frequent starts are necessary, particularly for higher inertia loads. These motors are commonly employed to drive compressors, pumps, machine tools, and conveyors. They are also found in AC compressors and refrigerators.

Capacitor Start & Capacitor Run Induction Motor:

The working principle of the capacitor run induction motor is akin to that of the capacitor start induction motor. As we know, a single-phase induction motor is not self-starting due to the non-rotary type of magnetic field generated. To create a rotary magnetic field, induction motors require a phase difference. While in a split-phase induction motor, resistance is needed to create this phase difference, in capacitor-run motors, capacitors serve this purpose.

It's a fact that the current flowing through the capacitor influences the voltage. In capacitor start & capacitor start capacitor run type motors, there are two windings: the main winding and the starting winding. The starting winding is linked with the capacitor, allowing the current flowing through the capacitor to influence the applied voltage by a certain angle. These motors boast high starting torque and find application in grinders, conveyors, compressors, air conditioners, and more.

Shaded Pole Induction Motor:

This self-starting single-phase induction motor features a shaded pole, often made of copper, known as the shaded ring. The shaded ring serves a similar function to a secondary winding.

These motors only turn in one specific direction, and reversing the motor's movement is not possible. They exhibit high power losses, low power factor, and extremely low induced starting torque. Due to their compact design and low power ratings, the efficiency of these motors is poor. Shaded pole induction motors find application in small devices such as fans and relays due to their easy starting and low cost.

These motors are used in hairdryers, exhaust fans, table fans, air conditioning units, cooling fans, refrigeration devices, record players, projectors, tape recorders, and photocopying machines. They are also employed in electronic clocks and single-phase synchronous timing motors for initiation purposes.

Applications:

Single-phase induction motors find applications in various low-power and domestic as well as industrial settings. Some common applications include:

- Pumps

- Compressors

- Small fans

- Mixers

- Toys

- High-speed vacuum cleaners

- Electric shavers

- Drilling machines

Three-Phase Induction Motor:

These motors are self-starting and do not require capacitors, start windings, centrifugal switches, or other starting devices. Three-phase AC induction motors are extensively used in industrial and commercial applications. They are primarily of two types: squirrel cage and slip ring motors. Squirrel cage motors are favored for their rugged construction and simple design, while slip ring motors require external resistors for high starting torque.

Induction motors are preferred in industrial and domestic appliances due to their rugged construction, low maintenance requirements, affordability, and the need for supply only to the stator.

Types of 3 Phase Induction Motor:

A 3-phase induction motor consists of two essential components: the stator and the rotor. The stator remains stationary, while the rotor rotates. The load is connected to the rotor shaft. The stator can be wound with three-phase armature winding, which, when supplied with balanced 3-phase current, generates a stable amplitude rotary magnetic field in the air gap.

These motors are classified into two types based on construction: Squirrel Cage Rotor and Wound Rotor.

Squirrel Cage Induction Motor:

The construction of squirrel cage induction motors is straightforward. The rotor comprises a cylindrical core with slots on the outer periphery. These slots are not identical and are skewed at certain angles to prevent magnetic locking between the stator and rotor teeth, ensuring smooth operation and reducing humming noise. The rotor bars, usually made of brass, aluminum, or copper, are short-circuited at both ends by end rings, resembling a squirrel cage, hence the name.

Wound Rotor or Slip Ring Induction Motor:

Also known as a wound rotor motor, the slip ring induction motor features a laminated cylindrical core with slots on the outer periphery. The rotor winding is placed inside these slots. Unlike the squirrel cage rotor, the rotor windings in a wound rotor motor are wound similarly to the stator and are typically connected in the STAR configuration. The terminals of this STAR connection are brought out through slip rings, hence the name slip ring induction motor.

Why is a 3-Phase Induction Motor Self Starting?

In a 3-phase motor, the three single-phase lines have a phase difference of 120°. Consequently, the rotary magnetic field also has a similar phase difference, causing the rotor to rotate. As each phase gets magnetized sequentially, the rotor follows the magnetic field, resulting in continuous rotation.

Why Single-Phase Induction Motor is not Self Starting?

When a single-phase supply is provided to a single-phase induction motor, it generates a pulsating magnetic field rather than a revolving one. The current passing through a conductor produces a flux that can be divided into two components, each rotating in the opposite direction at the same speed. As a result, the net flux becomes zero, inducing zero current in the rotor conductors and zero torque. Hence, a single-phase induction motor is not self-starting.

To address this issue and make the motor self-starting, it can be temporarily converted into a two-phase motor during starting. For this purpose, an additional winding called the starting winding is added to the main winding of the single-phase motor's stator. These windings are connected across the single-phase supply.

The windings are arranged so that there is a significant phase difference between the currents in the two stator windings, effectively making the motor operate like a two-phase motor. The resulting rotating flux enables the single-phase motor to become self-starting.

Advantages:

Induction motors offer several advantages due to their construction and mode of operation:

Low Cost: Induction motors are inexpensive compared to synchronous and DC motors, primarily due to their simple design. This makes them the preferred choice for fixed-speed applications in industrial, commercial, and domestic settings where AC line power is readily available.

Low Maintenance Cost: The simplicity of induction motor construction translates to easy maintenance, resulting in lower maintenance costs compared to DC and synchronous motors.

Ease of Operation: Induction motors operate simply without electrical connections to the rotor. Power and current are induced in the rotor by the transformer action of the stator coils, requiring minimal effort for operation. Additionally, induction motors are self-starting, reducing the need for manual intervention.

Speed Variation: Induction motors exhibit nearly constant speed variation, typically only varying by a few percent from no load to rated load.

High Starting Torque: Induction motors offer high starting torque, making them suitable for applications where a load is applied before motor starting. Three-phase induction motors inherently have self-starting torque, unlike synchronous motors. However, single-phase induction motors require auxiliary means to initiate rotation.

Durability: Induction motors are durable machines, capable of running for many years with minimal maintenance, making them suitable for a wide range of applications in industrial, domestic, and other settings.

These advantages make induction motors highly versatile and widely used in various applications.

Disadvantages:

Induction motors have several drawbacks, including:

Poor Power Factor: Under light load conditions, induction motors exhibit a low power factor and draw excessive current, leading to high copper losses and reduced efficiency.

Limited Initial Torque: Squirrel cage induction motors may lack sufficient initial torque.

Fixed Speed: Induction motors operate at a constant speed and are not suitable for applications requiring variable speeds.

Complex Speed Control: Speed control of induction motors is challenging.

High Starting Inrush Current: Induction motors experience a high starting inrush current, leading to voltage reduction during startup.

Applications:

Induction motors find diverse applications, including:

- Elevators

- Cranes

- Hoists

- Large capacity exhaust fans

- Lathe machines

- Crushers

- Oil extraction mills

- Textile machinery

In summary

Induction motors are classified into single-phase and three-phase types based on the input supply. Each type has various subcategories with specific characteristics, as discussed above. While single-phase motors are not self-starting, three-phase motors are.

Rlated Articles

Do ECM Motors Have Capacitors?

How Does a Single Phase Motor Work?

What is an Induction Motor :All You Need to Know

What L298 Motor Driver IC can do and How it Works