Exploring Solenoid Switches: Principles and Applications

Solenoid Switch is an electromagnetic switch that is often used to control the on and off of current. It consists of a coil and an iron core. When energized, the coil generates a magnetic field, causing the iron core to move due to attraction. This movement can be used to control the on and off of a circuit. Solenoid Switch is widely used in the automotive industry, electronic equipment, home appliances and other fields. In this article, we will explore the working principle, types and applications of Solenoid Switch.

Catalog

Ⅰ. Working Principles of Solenoid Switches

A.Discussion of the core components of solenoid switches

Ⅱ. Different Types of Solenoid Switches

Ⅲ. Applications of Solenoid Switches

Ⅴ.Future Trends of Solenoid Switch

Ⅵ.Briefly summarize Solenoid Switch

Summarize the importance and versatility of solenoid switches across various domains.Emphasize the irreplaceable role of solenoid switches in different industries.Encourage readers to delve deeper into further applications and innovative possibilities of solenoid switches.

Ⅰ. Working Principles of Solenoid Switches

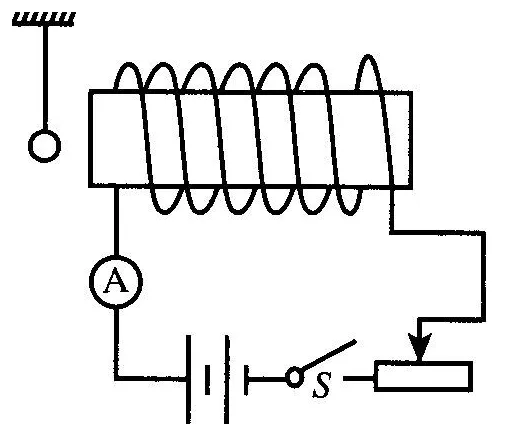

Figure1:Working Principles of Solenoid Switches

The working principle of a solenoid switch involves the use of electromagnetic force to control the switch's state. It consists of a coil of wire, called a solenoid, which, when an electric current flows through it, generates a magnetic field. This magnetic field interacts with a ferromagnetic core (typically a plunger or armature) located within the solenoid. The magnetic force attracts the core when the coil is energized, causing a mechanical movement. This movement of the core is responsible for triggering the switch action, either making or breaking an electrical connection, and thereby controlling the flow of current through the switch's contacts. Solenoid switches convert electrical energy into mechanical motion through electromagnetic force, making them essential components for remote or automatic control of electrical circuits.

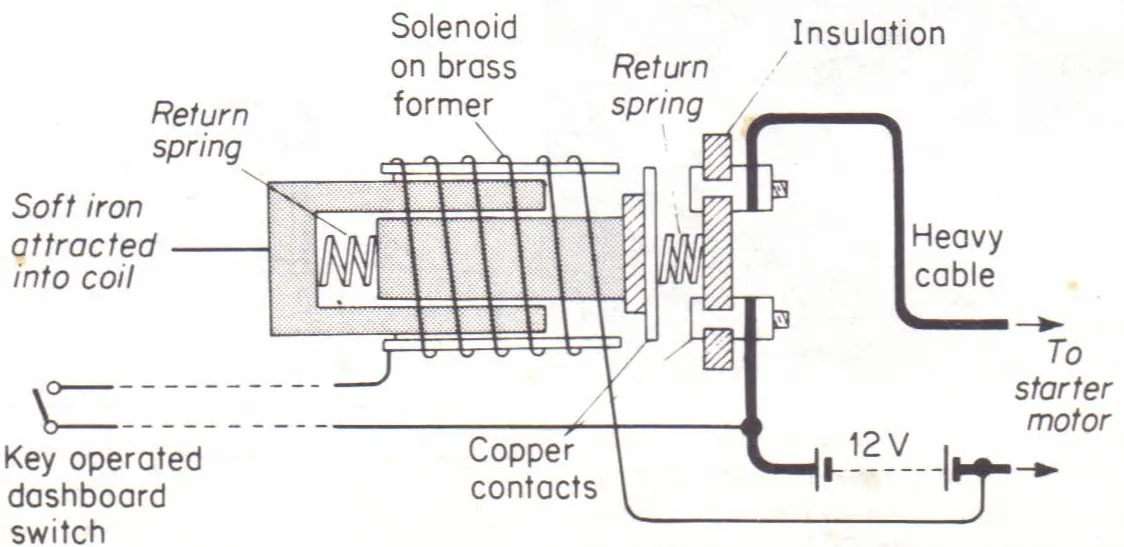

A.Discussion of the core components of solenoid switches

Figure2:core components of solenoid switches

Coil (Solenoid):

The coil is the primary component of the solenoid switch and is typically made of a wire wound around a cylindrical form. When an electric current passes through this coil, it generates a magnetic field. The strength and direction of this magnetic field depend on the direction and magnitude of the current flow. The coil's design is a key factor in determining the overall performance of the solenoid switch.

Magnet or Core:

The core of a solenoid is usually made from a ferromagnetic material, such as iron. This core enhances the magnetic effect produced by the coil. When the coil is energized and the magnetic field is generated, it interacts with the core to create a strong magnetic attraction. The core, often in the form of a plunger or armature, moves in response to this magnetic force.

Spring:

A spring is often incorporated in solenoid switches to provide a restoring force. It opposes the magnetic force created by the coil when it's energized. The spring is essential for returning the core or plunger to its original position when the coil is de-energized. This action helps in the reliable and stable operation of the switch.

Contacts:

The contacts in a solenoid switch serve as the electrical connection points. Depending on the design and application, these contacts can either be normally open (NO) or normally closed (NC). When the solenoid is energized and the core moves, it changes the state of these contacts, either closing an open circuit or opening a closed circuit. This action allows the switch to control the flow of electrical current within a circuit.

The synergy of these core components is what makes solenoid switches versatile and reliable in various applications. The coil generates the magnetic force, the core responds to it, the spring ensures proper return action, and the contacts manage the electrical connection or disconnection, enabling precise control in a wide range of scenarios.

Ⅱ. Different Types of Solenoid Switches

Solenoid switches come in various types, each with its specific design and function. Let's explore some of the different types of solenoid switches:

Single-Pole Solenoid Switch:

Figure3:Single-Pole Solenoid Switch

This type of solenoid switch has one set of contacts and is used to control a single circuit. When energized, it either opens or closes this circuit. Single-pole solenoid switches are commonly used in applications where a simple on-off control is needed.

Double-Pole Solenoid Switch:

Double-pole solenoid switches have two sets of contacts and can control two separate circuits simultaneously. When activated, they can open or close both circuits, offering more versatile control options. These switches are useful in scenarios where multiple functions need to be controlled with a single device.

Push-Pull Solenoid Switch:

Push-pull solenoid switches are designed to work with a pushing or pulling motion. When energized, they push or pull a plunger to actuate the switch. These switches are often used in applications where a linear motion is required to perform a specific task, such as locking mechanisms or latches.

Latching Solenoid Switch:

Latching solenoid switches are designed to maintain their last state even when the power is removed. They do not need a continuous power supply to remain in their current position, making them suitable for applications where power conservation is important. They are often used in battery-operated devices.

Rotary Solenoid Switch:

Instead of linear motion, rotary solenoid switches provide a rotary or rotational movement. They are used when there is a need to turn or rotate a component as part of the switching process, such as selecting different settings on a dial or switch.

Relays:

While not always called solenoid switches, relays are essentially switches that use a solenoid to control the switching action. Relays can come in various configurations, including single-pole, double-pole, and more, and are commonly used in control circuits to switch high-power loads using a low-power signal.

Each of these types of solenoid switches has unique characteristics that make them suitable for specific applications. The choice of solenoid switch depends on the particular requirements of the task or system they are intended to control.

Ⅲ. Applications of Solenoid Switches

Solenoid switches find applications in a wide range of industries and devices due to their versatility and reliability. Here's a brief introduction to some common applications:

Automotive Industry:

Solenoid switches are extensively used in automobiles for functions such as starting the engine (starter solenoid), controlling automatic transmissions, engaging and disengaging clutches, and managing fuel injection systems. They play a vital role in ensuring the smooth operation of vehicles.

Electronics and Appliances:

In consumer electronics and household appliances, solenoid switches are employed for various purposes, including power on/off switches, valve control in washing machines and dishwashers, and as part of locking mechanisms in doorbells and security systems.

Industrial Automation:

Industrial automation heavily relies on solenoid switches for controlling machines and equipment. They are used to actuate valves, open and close gates, and manage conveyor systems, making manufacturing and industrial processes more efficient.

Safety Systems:

Solenoid switches are crucial components in safety systems. They can be found in emergency shutdown systems, fire suppression systems, and door interlocks, ensuring quick and reliable responses in critical situations.

Locking Mechanisms:

Solenoid switches are used in various locking mechanisms, such as those in access control systems, vending machines, and electronic locks. They provide secure and convenient solutions for locking and unlocking devices.

Medical Equipment:

Medical devices and equipment often incorporate solenoid switches for tasks like controlling the flow of fluids, regulating pressure in medical instruments, and operating diagnostic and therapeutic devices.

Agricultural Machinery:

In farming and agriculture, solenoid switches are used for controlling irrigation systems, crop harvesting equipment, and various mechanical functions in agricultural machinery.

Aviation and Aerospace:

Solenoid switches are found in aircraft and spacecraft systems, ensuring precise control in critical applications like landing gear operation, valve actuation, and fuel management.

Telecommunications:

They are used in telecommunications equipment for switching and routing signals and managing connections in communication networks.

Power Distribution:

Solenoid switches are employed in power distribution systems for disconnecting or connecting circuits, as well as managing load shedding and other power-related functions.

These are just a few examples of the many applications of solenoid switches. Their ability to provide remote or automatic control of electrical circuits makes them essential in a wide range of industries and devices.

Ⅴ.Future Trends of Solenoid Switch

The future trends of solenoid switches are likely to be driven by advancements in technology and the increasing demand for efficiency and automation. Some potential trends to watch for include:

Smart Integration:

Solenoid switches are expected to become smarter with the integration of digital controls and communication protocols. This would enable them to be part of the Internet of Things (IoT) and connected systems, offering remote monitoring and control capabilities.

Energy Efficiency:

There's a growing emphasis on energy conservation, and solenoid switches are likely to be designed with improved energy efficiency in mind. This could involve the use of low-power solenoids, better materials, and optimized designs to reduce power consumption.

Miniaturization:

As technology continues to shrink in size, solenoid switches are expected to follow suit. Smaller and more compact solenoid designs will be essential for applications in miniaturized devices and electronics.

Materials and Manufacturing Advances:

Advances in materials science and manufacturing processes may lead to more durable and cost-effective solenoid components. For example, 3D printing could revolutionize the design and production of solenoids.

Environmental Sustainability:

There may be a push for more environmentally friendly solenoid switches, with a focus on materials that are easier to recycle and dispose of responsibly.

Advanced Control Algorithms:

Solenoid switches could benefit from more sophisticated control algorithms, allowing for precise and adaptive control in complex systems.

Safety and Reliability Enhancements:

Improvements in solenoid switch technology may lead to even higher levels of safety and reliability, making them suitable for critical applications in aerospace, medical devices, and other industries where reliability is paramount.

Customization:

Customized solenoid switches tailored to specific applications may become more prevalent, ensuring that each switch is optimized for its intended use.

These trends are driven by the increasing need for efficiency, automation, and connectivity in various industries and applications. Solenoid switches will continue to evolve to meet these demands while also adhering to emerging standards and regulations.

Ⅵ.Briefly summarize Solenoid Switch

Figure4:Solenoid Switch

A solenoid switch is an electromechanical device used in various applications across industries. It consists of a coil that generates a magnetic field when an electric current passes through it. This magnetic field interacts with a ferromagnetic core (plunger) and, in some designs, a spring to create a mechanical movement. Solenoid switches can be of various types, including single-pole, double-pole, push-pull, latching, and rotary, each with distinct functions. They find applications in the automotive, electronics, industrial automation, safety systems, medical equipment, and many other fields. Future trends for solenoid switches include smart integration, energy efficiency, miniaturization, and advancements in materials and manufacturing processes. These trends reflect a growing emphasis on sustainability, safety, and reliability, while also catering to the demand for more advanced and efficient control in various devices and systems.

Related Articles

Principle, Structure and Fault Analysis of Centrifugal Switch

Operation & Fault Handling of High Voltage Switchgear Explained

Zero Speed Switch : Principle & Its Applications