What is an Mechanical Comparator?

Typically, comparators serve for linear measurements, and presently, there are various types available, each differing in their methods of amplification and recording of measured variations. Engineers nowadays aim to classify comparators into high and low amplification categories, reflecting the intricacies of the underlying technology. Comparators are categorized based on the amplification and recording principles utilized, including mechanical, mechanical-optical, electronic, electrical, pneumatic, as well as other types like multi-check and projection comparators. These comparator variations offer users flexibility in selecting an appropriate and cost-effective option for specific metrological applications. This article provides an overview of a mechanical comparator, detailing its operation and applications.

What is a Mechanical Comparator?

A mechanical comparator is a measurement tool employing mechanical components such as gears, levers, pinions, and racks to achieve magnification. These components are utilized to amplify the movement of the mechanism, thereby improving the instrument's precision. The mechanical comparator diagram is illustrated below.

Working Principle of the Mechanical Comparator

The operational principle of a mechanical comparator involves employing mechanical mechanisms to amplify minute discrepancies. In all mechanical comparators, the method of magnifying the slight movement of the indicator is accomplished through a gear train and levers. These comparators typically offer magnifications ranging from 300 to 1000. Additionally, the mechanical comparator, also referred to as a "microcator," is utilized for linear measurements using the relative contact method.

Types of Mechanical Comparators

There are various types of mechanical comparators, including:

- Dial Indicators

- Read Type Comparators

- Johanson Mikrokator

- Sigma Comparators

- Dial Indicators

A dial indicator represents a straightforward mechanical comparator known for its sensitivity and versatility. It employs a gear system in conjunction with a pinion and rack. This type of comparator operates on the principle of the rack and pinion system, whereby the linear movement of the spindle is amplified through the arrangement of the rack and pinion.

The dial indicator mechanical comparator is utilized for assessing geometric deviations such as roundness, taper, ovality, and others. It is instrumental in identifying errors in alignment, surface quality, squareness, parallelism, and more.

- This comparator serves to assess two heights or distances within narrow margins.

- It is employed to examine the compression and tension of materials.

- It is utilized to authenticate the precision of milling machine arbors.

- It is employed to validate the alignment of lathe machine centers using a bar placed between them.

Read-type Comparator

A Reed-type mechanical comparator functions by comparing the dimensions of a workpiece against standard dimensions. While its external appearance resembles that of other mechanical comparators, its internal construction and operational principle are comparatively straightforward.

In this variant of mechanical comparator, the linear movement of the plunger is determined solely through the read mechanism. Initially, the comparator is calibrated with a known dimension, and subsequently, the indicator reading is adjusted to zero. When the measured part is positioned beneath the pointer, the comparator indicates the deviation in dimension.

Johanson Mikrokator

The Johansson Mikrokator, a mechanical comparator, was conceived by a Swedish engineer named H. Abramson and later produced by the Swedish company C.H. Johansson Ltd. It serves primarily as a comparing and measuring device and is esteemed for its uncomplicated design and operational principle.

The Johansson Mikrokator represents one of the simplest mechanical comparators, relying on a button-spinning mechanism attached to a string loop. As the measuring plunger moves up or down via a bell crank lever, the strip undergoes a change in length due to the lever's action. This change in strip length causes the glass pointer to move proportionally to the plunger's movement.

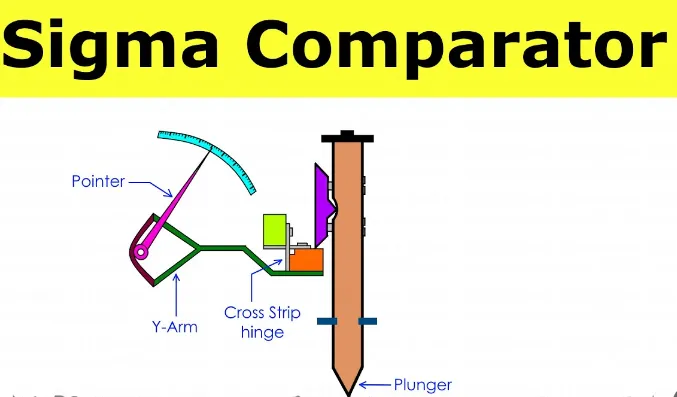

Sigma Comparator

The Sigma comparator is a type of mechanical comparator introduced by a US-based instrument manufacturing company. Primarily utilized for measuring surface roughness, it determines the dimensional variance between the standard and measured values of surface materials. This comparator typically achieves a magnification range of 300 to 500, with a compression spring regulating the measuring pressure. The magnification level attained is contingent upon the length of the levers on either side of the pivot.

Comparison Between Mechanical Comparator and Electrical Comparator

Distinguishing characteristics between mechanical and electrical comparators are as follows:

| mechanical comparator | electrical comparators |

| A mechanical comparator is a measurement device constructed with mechanical components to achieve magnification. | An electrical comparator is an electro-mechanical measuring apparatus designed with electrical components to achieve magnification. |

| This comparator incorporates numerous moving components. | This comparator incorporates a reduced number of moving components. |

| The presence of a greater number of moving parts in this system results in elevated wear and friction rates. | The presence of fewer moving parts in this system results in diminished wear and friction rates. |

| This comparator has moderate accuracy. | This comparator boasts high accuracy. |

| Variations within the power supply do not impact the readings of this comparator. | The readings of this comparator are influenced by variations within the power supply. |

| Maintenance for this comparator is straightforward. | Maintenance for this comparator is not straightforward. |

| It is cost-effective. | It is not cost-effective. |

| This is self-powered. | This comparator requires an external power source. |

| This comparator is highly susceptible to vibrations. | This comparator exhibits low sensitivity to vibrations due to its fewer movable parts. |

| The magnification range is relatively limited compared to the electrical type. | The magnification range is broader. |

Advantages

The advantages of mechanical comparators are as follows:

- Mechanical comparators offer cost-effectiveness compared to alternative amplification mechanisms.

- These devices operate independently of external electrical power sources.

- They provide exceptionally high levels of magnification.

- Their optical levers are lightweight, enhancing ease of use.

- Their linear scales facilitate straightforward comprehension.

- Mechanical comparators are compact, robust, and simple to operate.

- They are well-suited for typical workshop environments and are convenient to handle.

Disadvantages

The disadvantages of mechanical comparators are as follows:

- Mechanical comparators feature a higher number of moving components, leading to decreased accuracy and increased friction.

- Accuracy may decrease due to any oversight in the maintenance of moving parts.

- These comparators exhibit higher inertia, making them susceptible to vibrations.

- Their measuring range is restricted once the pointer exceeds a predefined scale.

- They suffer from a high degree of parallax error due to the movement of the pointer along a fixed scale.

- Integrating adjustments to the magnification can be exceedingly challenging.

Applications

The applications of mechanical comparators encompass the following areas:

- The reed-type mechanical comparator is primarily employed to gauge the dimensional deviation of workpieces against standard dimensions.

- These comparators find widespread use in mass production and laboratory testing for analytical purposes.

- They are commonly utilized across various manufacturing sectors, including outer rings, bearing inner parts, bearing cages races, and cylindrical components in automobiles.

- Mechanical comparator mechanisms are integrated into micators/small spring measuring heads, minicators/spring-lever indicators, and opticators/spring-optical measuring heads.

- Mechanical optical comparators leverage both mechanical and optical elements to amplify the movement of the plunger.

- They are valuable tools for measuring surface roughness by comparing the dimensional disparities between standard and measured surface values.

In summary

Mechanical comparators serve as linear measurement devices ideal for verifying numerous identical dimensions. While they do not provide actual workpiece dimensions, they indicate variations in size relative to a set dimension throughout the measurement. While unable to function as standalone measuring devices, comparators excel at comparing two dimensions. Available in various types to suit diverse conditions, these comparators feature magnifying mechanisms that amplify deviations from the standard size. Now, let me ask you: what exactly is a comparator?

Related Articles

Why Using Op Amps as Comparators?