Comprehensive Guide to Common Sensors

Sensors are tools used by humans to perceive, acquire, and detect various information from the natural world, providing a wealth of data that human senses alone cannot obtain. In modern science and technology, industrial and agricultural production, as well as daily human life, sensors play an irreplaceable role. It can be said that the more advanced science and technology become, and the higher the level of automation, the greater the dependence on sensors.

Composition and Classification of Sensors

Composition of Sensors

Sensors generally comprise sensitive elements, transducer elements, and fundamental conversion circuits, as depicted in Figure 1.

Sensitive elements are components capable of sensitively perceiving the measured phenomenon and responding according to a defined relationship.

Transducer elements convert the measured quantity sensed by sensitive elements into circuit parameters (such as resistance, inductance, and capacitance) or electrical quantities (such as voltage and current).

Basic conversion circuits convert the output of transducer elements into electrical quantities that are convenient for transmission and processing.

Some sensors may consist only of sensitive and transducer elements, while for some sensors, the sensitive and transducer elements can be combined into one. The simplest sensors are composed of a single sensitive element (which also serves as a transducer element), capable of directly outputting electrical quantities when measuring, such as thermocouples, piezoelectric crystals, and photovoltaic cells.

Classification of Sensors

There exist numerous types of sensors, and they can be classified using various methods. In this context, we will introduce two of the most commonly employed classification techniques.

(1) Classification by measured physical quantity. Sensors encompass a wide range of types, such as displacement sensors, proximity sensors, velocity sensors, temperature sensors, force sensors, torque sensors, pressure sensors, acceleration sensors, and many more. This classification method directly indicates the purpose of the sensors, corresponding to the types of information to be measured that users and sensor manufacturers are concerned about, making it easier for users to understand and select sensors.

(2) Classification by working principle. Sensors comprise various types, including resistive sensors, capacitive sensors, inductive sensors, piezoelectric sensors, Hall sensors, optoelectronic sensors, and several others. This classification method is based on the working principle of sensors, facilitating people's understanding and research on various sensors and their detection principles.

Basic Characteristics of Sensors

The characteristics of sensors pertain to the correlation between the output and input quantities of the sensor. Since the input quantity has two basic forms: static (i.e., the input signal remains unchanged with time or changes very slowly in a fundamentally stable state) and dynamic (i.e., the input signal varies periodically with time or changes irregularly in transient states), the characteristics of sensors typically have two corresponding representations: static characteristics and dynamic characteristics.

When the input quantity is static, the relationship between the output and input quantities of the sensor is called the static characteristics of the sensor. Commonly, the primary parameters employed to define the static characteristics of sensors comprise measurement range, full scale, sensitivity, resolution, linearity, time lag, repeatability, drift, and stability.

Characteristics of Common Sensors

Proximity Sensors

Proximity sensors have the capability to detect the presence of an object in close proximity without physical contact and convey the detection outcomes through switch signals. Hence, they are often referred to as non-contact travel switches or proximity switches.

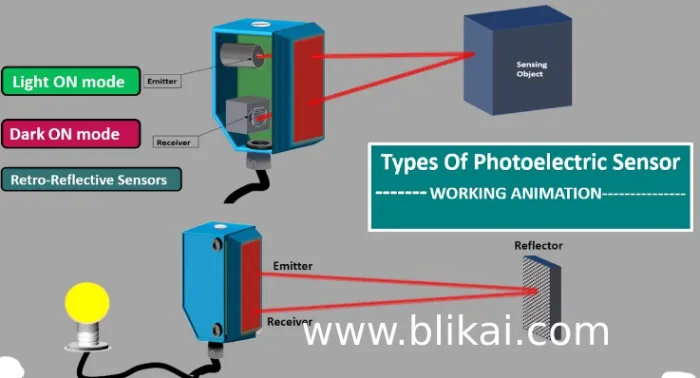

Proximity switches include various types such as inductive, capacitive, photoelectric, and Hall effect sensors.

(1) Inductive Proximity Sensors: Inductive proximity sensors, also known as inductive proximity switches or eddy current proximity switches, mainly consist of LC high-frequency oscillation circuits, signal processing circuits, and switch amplification circuits.

(2) Capacitive proximity sensors, commonly referred to as capacitive proximity switches, employ the plates of a capacitor as their sensing surface. The material positioned in front of the sensing surface acts as the insulating medium between the two capacitor plates. Any changes in this insulating medium will result in a corresponding change in the capacitance of the capacitor.

Regardless of whether the object detected is metal or non-metal, as it approaches or moves away from the capacitive proximity switch, there will be a variation in the dielectric constant of the capacitor within the proximity switch. This alteration enables the capacitive proximity switch to generate the appropriate switch signal.

Thus, the objects detected by capacitive proximity switches are not limited to metallic conductors; they can also be insulating liquids or powdered substances. An example of a capacitive proximity switch in use is shown in Figure 2.

(3) Photoelectric proximity sensors are a category of sensors that employ photoelectric devices to transform light signals into electrical signals. The core sensitive element is the photoelectric device, which operates based on the photoelectric effect. Figure 6 shows a photoelectric proximity switch.

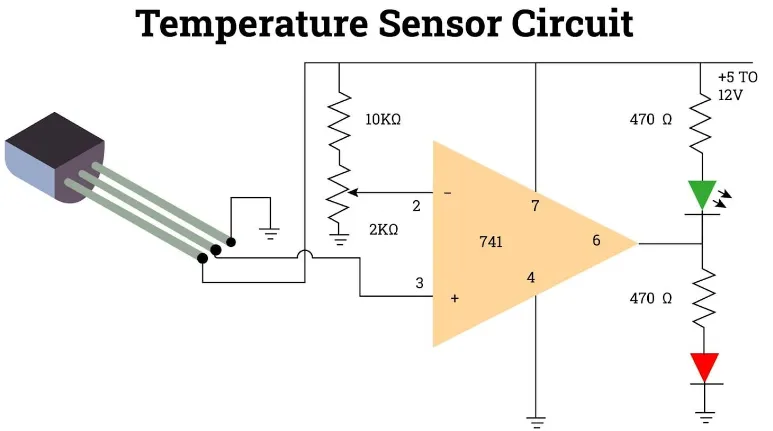

Temperature Sensors

To meet the temperature measurement requirements of different occasions and substances, there are two methods of temperature measurement: contact and non-contact. The former involves direct physical contact between the temperature-sensitive element and the object being measured, measuring temperature through heat conduction; while the latter does not involve physical contact between the temperature-sensitive element and the object being measured, instead measuring temperature through thermal radiation.

Each method of temperature measurement corresponds to its specific type of temperature sensor. Contact temperature sensors typically utilize the temperature characteristics of materials or components for temperature measurement. Commonly used temperature sensors include thermocouples, thermal resistors, thermistors, and integrated temperature sensors, among others. Figure 3 shows a temperature sensor Pt100 and a temperature transmitter commonly used in equipment.

Magnetic Switches

In automated production lines, magnetic switches are used for position detection of various types of cylinders. Two magnetic switches are used to detect the extended and retracted positions of cylinders on a robotic arm.

Magnetic proximity switches, also known as magnetic switches, are position detection switches that operate without physical contact. This non-contact detection method eliminates wear and damage to the detected object and ensures a rapid response.

Magnetic switches are designed to detect the presence of magnetic materials and can be installed in various configurations, including lead wire type, plug-in type, and plug-in relay type.Depending on the environmental requirements of the installation location, magnetic switches can be shielded or unshielded.

Fiber Optic Photoelectric Proximity Switches

Fiber optic photoelectric proximity switches, also known as fiber optic photoelectric switches, belong to the category of fiber optic sensors. The sensing component of a fiber optic sensor lacks circuit connections and remains non-heat generating, relying solely on minimal optical energy. These characteristics make fiber optic sensors an ideal choice for hazardous environments.

Fiber optic sensors can additionally serve for continuous, dependable monitoring of vital production machinery over extended periods.In scenarios where production operations entail risks such as explosions or fires due to factors like smoke or sparks, optical energy poses no ignition risk, effectively averting potential explosions and fires. Compared to traditional sensors, fiber optic sensors have the following advantages: resistance to electromagnetic interference, ability to operate in harsh environments, long transmission distances, and long service life. Additionally, due to the small size of fiber optic heads, they can be installed in very small spaces. Fiber optic amplifiers can be set up as needed.

For example, in production processes where smoke, sparks, etc., may cause explosions and fires, optical energy will not become a source of ignition, thus preventing explosions and fires. Fiber optic detection heads can be installed in hazardous areas, while amplifier units can be installed in non-hazardous areas for use

Fiber optic sensors are composed of fiber optic detection heads and fiber optic amplifiers, featuring separate components for the amplifier and detection head.Fiber optic sensors are structurally divided into sensing type and transmitting type. The sensing type uses the fiber optic itself as the sensitive element, allowing the fiber optic to sense and transmit the measured information.

The transmitting type inputs modulated light signals from the object being measured into the optical fiber, measures them through the output end for light signal processing, similar to the working principle of photoelectric sensors. In production, the sorting unit of goods often uses transmitting-type fiber optic photoelectric switches, with the fiber optic serving only as a transmission line for modulated light. Common fiber optic sensors are shown in Figures 4.

Photoelectric Encoder

A photoelectric encoder is a sensor that converts mechanical or geometric displacement into pulses or digital quantities through photoelectric conversion. It is mainly used for speed or position (angle) detection.

A standard photoelectric encoder comprises a code disk, a detection grating, photoelectric conversion circuitry (comprising a light source, photosensitive device, and signal conversion circuit), mechanical components, and other associated elements.

Generally, based on the way pulses are generated by the photoelectric encoder, it can be divided into three main types: incremental, absolute, and hybrid. Incremental sensors are commonly used in production lines.

In general production equipment, conveyor belt positioning control is accomplished using photoelectric encoders. Furthermore, photoelectric encoders find application in measuring motor speeds.

Hall Sensor

A Hall sensor is a magnetic sensor based on the Hall effect. When an electrically charged object is placed in a magnetic field, if the direction of the electric current is perpendicular to the direction of the magnetic field, a transverse voltage will be generated in the direction perpendicular to both the magnetic field and the electric current. This occurrence is termed the Hall effect, and the voltage produced as a consequence is referred to as the Hall voltage.

Hall devices are made from semiconductor materials that exhibit significant Hall effects. Hall sensors serve as the magneto-electric conversion element, enabling them to be utilized for electromagnetic measurements, including the measurement of magnetic fields, currents, electrical power, and other magnetic and electrical physical quantities. Hall sensors can also utilize magnetic fields as a medium to achieve non-contact measurements of many physical quantities.

Hall sensors play a crucial role in various industries, transportation systems, communication devices, automatic control systems, and household appliances by converting non-electrical quantities such as force, displacement, vibration, acceleration, velocity, and flow rate into electrical signals.

Based on the functionality of Hall devices, they can be divided into Hall linear devices and Hall switch devices. The former outputs analog signals, while the latter outputs digital signals.

Based on the nature of the detected object, their applications can be divided into direct applications and indirect applications. The former method directly detects the magnetic field or magnetic properties of the object under test, whereas the latter method detects a magnetic field deliberately applied to the object under test, utilizing this magnetic field as a carrier for the information being assessed. Through this process, numerous non-electric and non-magnetic physical attributes such as force, torque, pressure, stress, position, displacement, velocity, acceleration, angle, angular velocity, number of rotations, rotational speed, and alterations in operational states over time are transformed into electrical quantities for detection and control purposes.

Hall devices are divided into two major categories: Hall elements and Hall integrated circuits. The former is a simple Hall chip, and amplification of the obtained Hall voltage is often required for use. The latter integrates the Hall chip and its signal processing circuit on the same chip.

Hall elements can be made from various semiconductor materials, such as Ge, Si, InSb, GaAs, InAs, InAsP, and multilayer semiconductor heterostructure quantum well materials, among others.

Resistive Sensors

Resistive sensors are devices that convert physical quantities such as displacement, deformation, force, acceleration, humidity, temperature, etc., into resistance values. There are mainly resistive strain gauges, piezoresistive sensors, thermistors, thermosensitive, gas-sensitive, humidity-sensitive, and other resistive sensor components.

Resistive Strain Gauge Sensors

The resistive strain gauge within the sensor exhibits the strain effect of the metal, meaning it experiences mechanical deformation in response to external forces, consequently resulting in a corresponding alteration in resistance value. Resistive strain gauges are mainly divided into two categories: metal and semiconductor. Metal strain gauges include wire, foil, and thin film types. Semiconductor strain gauges have advantages such as high sensitivity (usually tens of times that of wire or foil) and low transverse effects.

Piezoresistive Sensors

Piezoresistive sensors are constructed utilizing semiconductor materials that exploit the piezoresistive effect. These sensors incorporate semiconductor materials diffused into the substrate, enabling them to detect changes in resistance in response to mechanical stress or strain. The substrate can function directly as the measurement sensing element, with the diffused resistance forming a bridge inside it. When the substrate experiences deformation from an external force, the resistance values alter, leading to an imbalanced output from the bridge.

The materials commonly employed for the substrate or membrane of piezoresistive sensors are primarily silicon and germanium wafers. Silicon wafers fabricated from sensitive materials are increasingly vital for piezoresistive sensors, particularly for solid-state piezoresistive sensors widely employed in pressure and velocity measurement applications.

Final thoughts

We provide basic knowledge and classification of commonly used sensors, including their fundamental principles, common types, and operational principles. This information covers the applications of sensors in measuring and detecting various physical quantities, as well as the characteristics and advantages of different types of sensors. Thank you for your offer! If I have any further questions about sensors or any other topics, I'll be sure to reach out. Buy sensors, visit Blikai Mall.

Related Articles

Intelligent Sensors: Definition, Configurations, and Utilizations